| |

Traditionally blower

performance and the related specifications, with ever increasing air velocities, has been the focus for blow

off system comparison. The higher velocities are

presumed to translate into increased drying performance.

However, as is evident when evaluating these systems on

site, this is not always the case. To create high

velocity air, high speed fans operating at 3,600 rpm are

the usual choice. This selection in turn produces a high

frequency whine and an overall increase in noise level.

Although the fan specifications are important and air

velocities are relevant, what is obviously more

important is surface impact air velocity.

increasing air velocities, has been the focus for blow

off system comparison. The higher velocities are

presumed to translate into increased drying performance.

However, as is evident when evaluating these systems on

site, this is not always the case. To create high

velocity air, high speed fans operating at 3,600 rpm are

the usual choice. This selection in turn produces a high

frequency whine and an overall increase in noise level.

Although the fan specifications are important and air

velocities are relevant, what is obviously more

important is surface impact air velocity.

The

"Performance Option"

All blower manufacturers' fans can be selected to

conform to similar specifications. If the blower is then

connected to a conventional blow off delivery system

(combinations of knife or slotted nozzles) then the

combination is limited by the characteristics of that

blow off delivery system. This is where the Pioneer

System is superior to the others.

Production line water blow off systems can be classified

into two distinct and separate areas:

Blower Performance:

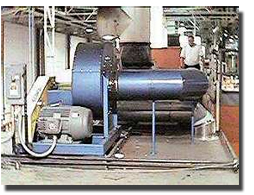

Pioneer manufactures its own fans and housings to

guarantee the highest quality control and to allow for a

greater degree of custom mountings. The fan greater degree of custom mountings. The fan

is built to

meet and exceed automotive industry standards,

incorporating 1750 rpm motors, 1/2 the speed of

conventional systems. This reduced fan speed eliminates

the whine, while the larger fan diameter and associated

duct work reduces the overall noise levels. AMCA

certification available. is built to

meet and exceed automotive industry standards,

incorporating 1750 rpm motors, 1/2 the speed of

conventional systems. This reduced fan speed eliminates

the whine, while the larger fan diameter and associated

duct work reduces the overall noise levels. AMCA

certification available.

Delivery System:

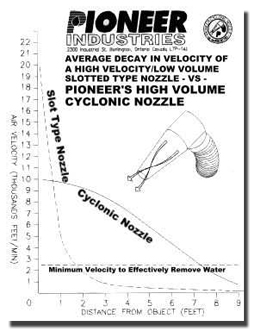

At the heart of the Pioneer Blow Off System is our

unique patented cyclonic nozzle. This nozzle is capable

of delivering air at higher velocities to any surface

over much greater distances than conventional systems.

By dividing the air flows into many separate air streams

it becomes possible to be very selective as to the point

of impact. This feature makes it possible to dry

multi-faceted shapes. Pioneer Blow Off Systems are

currently drying shapes as varied as automotive facia,

steel office cabinets, full car and truck body shells

and equipment as large as farm vehicles and railway

locomotives.

The cyclonic blow off nozzle delivery system is used

exclusively in all our patented cyclonic blow off

systems. |

|