| |

Throughout the years there has been an ever-increasing

demand for specialty cleaning. Pioneer has developed,

many new and innovative ways of dealing with difficult

cleaning and maintenance issues in industry, including

auto body and parts carriers.

Now operations such as:

Removal of paint accumulation ("Corn Flakes") on

critical carrier reference points.

Surface abrasion to highlight defects and/or prepare

surfaces for coating.

On-line, constant maintenance of carriers, bucks and

fixtures.

Removal of welding slag or spatter.

Brushing castings of residual casting flash or

mould

sand.

These can all be addressed with an innovative Pioneer

Cleaning System.

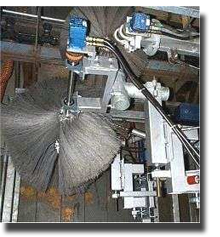

Here a Pioneer wire brush system is used to remove

excess "E" coat from sensitive areas of this automotive

body carrier. Note the abraded/clean areas contrast to

the grey "E" coated areas. Pioneer silicon carbide

impregnated nylon brushes with grits ranging from 50 - 600

have many applications and can be used to keep critical

areas of body carriers clean, pre-treat a "body in

white", remove galvanized defects, or pre-treat the "E"

coat prior to paint. Combinations of different types of

wire brushes can be used, from "zigzag" sections, tight

dimensional brushes for tight areas and even

"knot-wheel" brushes for really aggressive abrasion. A

Pioneer Cyclonic

Blow-Off can be used to clear the work

area of debris. Blow-Off can be used to clear the work

area of debris.

For surfaces where mechanical abrasion with wire

bristles may mar the surface or where the material is

too rubbery to be effectively removed, Pioneer uses

nylon bristles impregnated with abrasive particles.

These brushes come in varying densities and grit factors

to suit any purpose. These versatile bristles have been

used to lightly sand galvanized truck and car body

panels in Pioneer systems. The bristles automatically

contour to every surface and profile to create a lightly

scuffed surface that greatly enhances paint and coating

adhesion, while at the same time removing "galvanizing

imperfections" and high spots reducing paint defects.

For heavy use a coarse grit brush can be used for

aggressive action. Two grit types are available -

aluminium oxide and silicon carbide impregnated

throughout tough nylon filaments . panels in Pioneer systems. The bristles automatically

contour to every surface and profile to create a lightly

scuffed surface that greatly enhances paint and coating

adhesion, while at the same time removing "galvanizing

imperfections" and high spots reducing paint defects.

For heavy use a coarse grit brush can be used for

aggressive action. Two grit types are available -

aluminium oxide and silicon carbide impregnated

throughout tough nylon filaments .

Specialty Conveyors Require

Specialty Cleaning

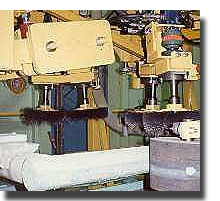

Pioneer systems are custom made for each application, here another

auto body carrier cleaning system was

introduced to dramatically reduce the requirement to

have carrier debris "burned off" thereby reducing

harmful fume emissions and introducing a vast savings in

lower equipment operation costs.

This unit was suspended from building columns and roof

supports. Pioneer designed the housing structure and

provided all the skinning sheet metal, grating supports

and maintenance access walkways. All brushes are mounted

on completely adjustable arms to finely tailor brush

contact points.

Complete System Design

Pioneer can fully engineer your system from the ground

up. Including all structures, electrical controls and

pumping systems. No

cleaning situation is alike in industry, every

different problem requires a slightly different

approach. Here cleaning situation is alike in industry, every

different problem requires a slightly different

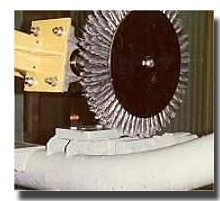

approach. Here a Pioneer System is used with tight

dimensional wire brushes and in the lower view, a tight

"knot-Wheel" brush to effectively abrade and remove

build-up on critical body location pins on an auto body

carrier. A positive hydraulic drive provides ample

rotational power and is easily varied for both speed and

torque (providing automatic stall control). This gives

an almost unlimited amount of adjustability unequalled by

other drives such as electric. Pioneer manufactures

hydraulic units specifically tailored to your system

needs, complete with standardized components for easy

repair. a Pioneer System is used with tight

dimensional wire brushes and in the lower view, a tight

"knot-Wheel" brush to effectively abrade and remove

build-up on critical body location pins on an auto body

carrier. A positive hydraulic drive provides ample

rotational power and is easily varied for both speed and

torque (providing automatic stall control). This gives

an almost unlimited amount of adjustability unequalled by

other drives such as electric. Pioneer manufactures

hydraulic units specifically tailored to your system

needs, complete with standardized components for easy

repair. |

|