| |

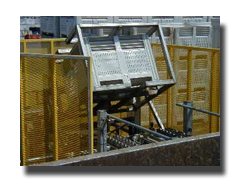

This system, as designed,

was built to receive plastic and wooden bins full of fruit, which has been loaded on an entrance feed conveyor. Each bulk bin is then to be automatically indexed into a dumping device. The dumping device will clamp the bin securely, rotate 115° and unload the fruit into a hopper. From this hopper the fruit is metered onto an inclined conveyor, size sorted and finally was built to receive plastic and wooden bins full of fruit, which has been loaded on an entrance feed conveyor. Each bulk bin is then to be automatically indexed into a dumping device. The dumping device will clamp the bin securely, rotate 115° and unload the fruit into a hopper. From this hopper the fruit is metered onto an inclined conveyor, size sorted and finally

enters the plant to be processed.

When the bin is empty the dumper will automatically lower and eject the bin at 90° to the index feed conveyor onto a transfer

conveyor which will transport the bulk bin to the first “Upender”. This device will turn the bulk bin upside down and place it at the entrance of the bin rinse system. enters the plant to be processed.

When the bin is empty the dumper will automatically lower and eject the bin at 90° to the index feed conveyor onto a transfer

conveyor which will transport the bulk bin to the first “Upender”. This device will turn the bulk bin upside down and place it at the entrance of the bin rinse system.

The bin rinse system utilizes a reservoir of water contained beneath the conveyor, to flush the interior and exterior of the bin of leaves, mud and other debris. Then 300 gallons of water per minute is flooded at 50 psi over the slow moving bulk bin, effectively submerging it, however

no

chemicals or hot water are used. A small volume of additional water is added constantly via a final fresh water rinse to maintain the water levels.

Upon leaving the rinse system the bulk bin is upended again and ejected down onto an inclined raceway where it is picked up by an operator and transported to storage no

chemicals or hot water are used. A small volume of additional water is added constantly via a final fresh water rinse to maintain the water levels.

Upon leaving the rinse system the bulk bin is upended again and ejected down onto an inclined raceway where it is picked up by an operator and transported to storage |

|