| |

Since 1984 Pioneer Industries has been involved in the washing and drying of diesel locomotives and passenger coaches. This technology is a simple step forward from Pioneers previous involvement in large vehicle washing systems such as delivery trucks, semi tractor-trailers and even diverse objects such as military tanks, aircraft wings and combine harvesters. Our standard washing methods were adapted and sized accordingly to accommodate the extreme size of trains and their specific cleaning requirements and methods as well as the accommodation for bi-directional washing...Washing the train coming OR going! objects such as military tanks, aircraft wings and combine harvesters. Our standard washing methods were adapted and sized accordingly to accommodate the extreme size of trains and their specific cleaning requirements and methods as well as the accommodation for bi-directional washing...Washing the train coming OR going!

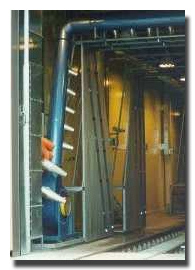

Pioneer Industries, engineers, designs and manufactures train wash systems from the ground up. Our Innovative solutions to water reclamation issues, water conservation concerns and the challenge of cleaning very large vehicles have created very effective and economical wash systems. Pioneer utilizes filament brushes and flood halos, coupled with chemical application systems to thoroughly clean the outer surfaces of diesel locomotives and rolling stock. Typically the Pioneer train wash is designed for one way operation. It however has been customized to include bi-directional operation offering the ultimate in usability. Tough washing environments like these are

where Pioneers' systems stand out, we design to excel and our systems are designed for rough service and are built to last! where Pioneers' systems stand out, we design to excel and our systems are designed for rough service and are built to last!

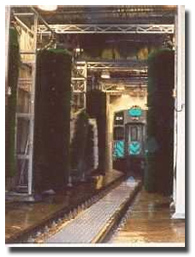

Pioneers full tunnel washes include all pre-rinse arches, chemical application arches, high pressure rinse, filament brush cleaning system (with counter rotating brushes), and finally the Pioneer Cyclonic Blow-Off. Revisions are available to allow dual direction washing. All of Pioneers systems are custom manufactured to suit the application and customer specifications This picture illustrates the full brush system of a dual direction system. This train is actually being washed while traveling BACKWARDS! This system was custom designed to accommodate extra high, two level rolling stock and multiple programmed wash cycles.

Pioneer offers a wide range of chemical application arches and specialty cladding for control of overspray. Base and Acid chemical arches can be incorporated in each system and can be selected as required. Foamers create a perfect coating for proper brush lubrication and cleaning action. Acid chemical arches can be incorporated in each system and can be selected as required. Foamers create a perfect coating for proper brush lubrication and cleaning action.

Here a Pioneer Cyclonic Blow-Off is utilized in a state of the art facility to blow-off diesel locomotives after a washing process. Pioneer's Cyclonic Blow-Off System offers the ultimate in performance. This 120hp system effectively removes water from double-decker coaches and diesels. Specific nozzles are included to concentrate on specific trouble areas such as doorways. No moving parts (except motors) and Low maintenance. Pioneer manufactures its own blowers to exacting standards. The Cyclonic Nozzle has a very long range and effectively removes water while staying well clear of the train. Of course, custom configuration is not a problem: All of our systems are tailored to YOUR situation.

Pioneer does it all!. The Pioneer train wash includes all necessary custom made pumping and computer control packages. Duplex configurations are available for "no down time" maintenance and repairs. Pioneer manufactures the pneumatic and hydraulic systems for our brush packages as well as the water reclamation systems, process pumping systems conveyor line systems and blower & filter units. |

|